The Heart of the Harvest: Unveiling the Modern Rice Processing Mill

Rice, a global dietary staple nourishing billions, undergoes a remarkable transformation from a raw agricultural product into the clean, edible grains that grace our tables. This intricate alchemy is performed within a Rice Processing Mill – a complex, interconnected system of machinery and processes designed for precision, efficiency, and quality. Far from being a simple structure, a modern rice processing mill is a sophisticated industrial facility, vital to ensuring food security and economic prosperity for rice-producing regions worldwide.

At Ricetec Machinery, with over two decades of dedicated experience in manufacturing and supplying cutting-edge grain processing solutions, we understand that a successful rice mill is more than just a collection of machines. It’s a precisely engineered ecosystem where every stage is optimized to maximize yield, minimize waste, and deliver a consistently superior product. We pride ourselves on designing, installing, and supporting complete rice processing mills that stand as benchmarks of efficiency and reliability.

The Journey Through the Mill: A Stage-by-Stage Transformation

The transformation of raw paddy into polished rice is a meticulously controlled journey, typically involving several distinct sections within the mill. Each section houses specialized machinery working in harmony to achieve the desired outcome.

1. The Reception and Pre-Cleaning Gateway

The journey begins as raw paddy arrives at the mill. Harvested paddy often carries field impurities like straw, leaves, dust, stones, and other foreign matter. The initial stages of the mill are dedicated to meticulously removing these contaminants.

- Paddy Intake System: This includes pits and conveyors where raw paddy is unloaded and channeled into the processing stream.

- Pre-Cleaners (Vibrating Sieves & Drum Cleaners): These machines employ vibrating screens or rotating drums to separate larger impurities like straw, stalks, and coarse debris from the paddy.

- De-stoners: Crucially, de-stoners use a combination of vibration and air currents to separate stones and other heavy particles based on their specific gravity. This step is paramount not only for product purity but also to protect downstream machinery from damage caused by hard foreign objects.

- Magnetic Separators (Optional but Recommended): For an added layer of protection, these units remove any metallic impurities that might be present in the paddy.

2. The De-husking Core: Unveiling Brown Rice

Once cleaned, the paddy moves to the de-husking section, where the tough, inedible outer husk is removed to reveal the brown rice kernel.

- Paddy Hullers (De-huskers/Shellers): The workhorse of this section, these machines typically utilize two rubber rollers rotating at different speeds. The differential speed gently yet effectively strips the husk off the paddy, minimizing damage to the delicate rice kernel.

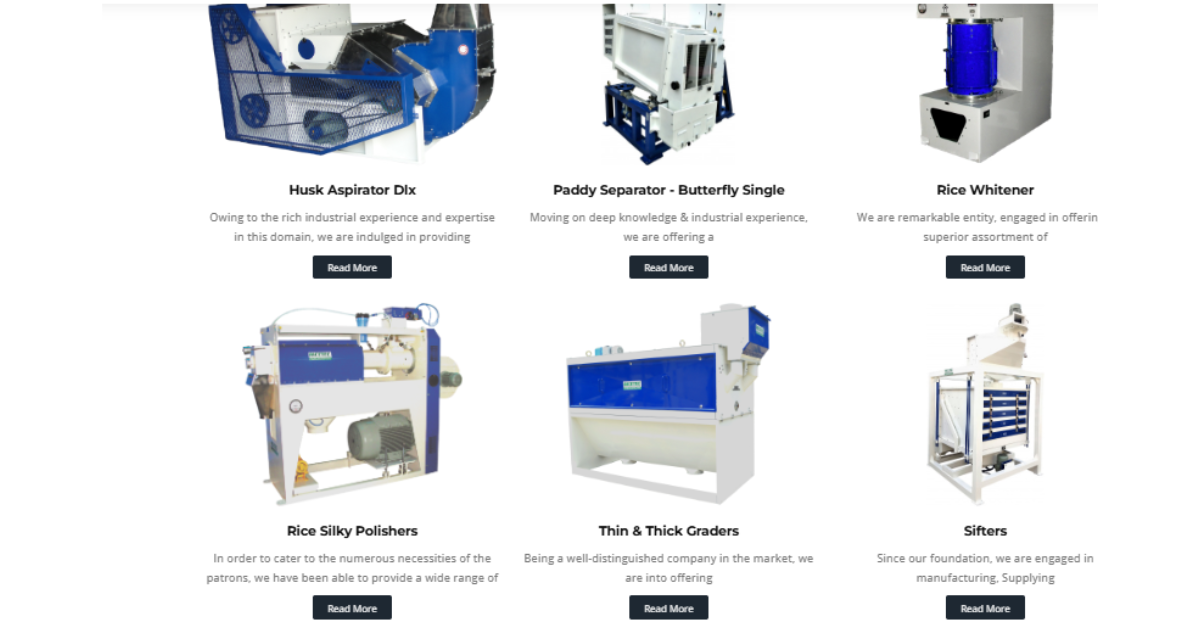

- Husk Aspirators: Immediately after hulling, powerful suction systems, known as husk aspirators, separate the lightweight husks from the heavier mixture of brown rice and any un-husked paddy. The collected husks are often a valuable by-product, used as biofuel within the mill or for other industrial applications.

3. The Paddy Separation System: Precision for Purity

Despite efficient hulling, a small percentage of paddy grains might pass through the hullers without being de-husked. The paddy separation section ensures that only properly de-husked grains proceed to the next stage.

- Paddy Separators: These ingenious machines, often utilizing multi-layered oscillating trays, separate the un-husked paddy from the brown rice based on their subtle differences in density, shape, and coefficient of friction. The separated un-husked paddy is then re-circulated back to the hullers for another pass, ensuring maximum efficiency and minimal waste.

4. The Whitening and Polishing Stages: Crafting the Desired Finish

Brown rice, while nutritious, still retains its bran layers, which give it a brownish color. The whitening section meticulously removes these layers to produce white rice, which is widely preferred by consumers.

- Rice Whiteners (De-branners): These machines employ either abrasive grinding wheels or friction-based rollers to gently rub off the bran layers. The degree of whitening can be precisely controlled, allowing for various levels of polish to meet specific market demands. Often, multiple whitening passes are used to ensure a gradual and gentle removal of bran, preserving kernel integrity.

- Silky Rice Polishers (Optional, but Enhances Value): For a premium finish, polished rice passes through a silky polisher. These machines apply a fine mist of water and use friction to create a smooth, lustrous, and translucent surface on the rice kernels, significantly enhancing their visual appeal and market value.

5. The Grading and Sorting Process: Ensuring Uniformity and Quality

After whitening and polishing, the rice grains are sorted meticulously to ensure uniformity in size and to separate broken grains from whole grains.

- Rice Sifters (Multi-deck Sifters/Plansifters): These machines use multiple vibrating screens with different mesh sizes to classify rice into various categories, such as head rice (whole grains), large broken rice, small broken rice, and rice tips.

- Length Graders: Specifically designed to separate rice kernels based on their length, ensuring that only full-length grains are classified as head rice, crucial for meeting stringent quality specifications.

- Thickness Graders (Optional): Used to remove underdeveloped or thin grains, contributing to a more uniform final product.

- Color Sorters (Optical Sorters): A cutting-edge technology that uses advanced optical sensors and high-resolution cameras to detect and eject discolored grains, chalky kernels, foreign materials, and other subtle defects that mechanical grading might miss. This ensures an exceptionally high level of purity and visual consistency in the final product.

6. Packaging and Ancillary Support Systems

The final stages prepare the milled rice for distribution and ensure the overall smooth operation of the mill.

- Weighing and Bagging Machines: Automated systems accurately weigh and fill the sorted rice into various bag sizes, ready for sale and shipment.

- Storage Silos/Bins: Essential for storing raw paddy before processing and for storing finished milled rice before dispatch, maintaining optimal conditions.

- Bucket Elevators & Conveyors: The arteries of the mill, these systems efficiently transport paddy and rice vertically and horizontally between different processing stages.

- Dust Collection Systems: Crucial for maintaining a clean and safe working environment and preventing air pollution by collecting dust generated during various processes.

- Centralized Control Panels & Automation: Modern mills are managed by sophisticated control systems that allow operators to monitor, adjust, and automate the entire process, minimizing manual intervention, optimizing efficiency, and ensuring consistent output.

The Ricetec Advantage: Crafting Superior Rice Processing Mills

At Ricetec Machinery, our commitment goes beyond just supplying machines. We deliver complete, integrated rice processing mill solutions engineered for:

- Maximum Yield & Profitability: Our mills are designed to achieve high head rice recovery and minimize broken grains, directly impacting your bottom line.

- Uncompromising Quality: Through precision engineering and advanced sorting technologies, our mills produce consistently high-quality, pure, and aesthetically appealing rice.

- Energy Efficiency & Sustainability: We integrate energy-saving designs and efficient by-product management systems (like utilizing husks for energy) to reduce operational costs and environmental impact.

- Robustness & Reliability: Built with superior-grade materials and meticulous craftsmanship, our mills are designed for continuous, heavy-duty operation with exceptional durability and minimal downtime.

- Scalability & Customization: Whether you require a compact mini rice mill or a large-scale commercial plant, we offer tailored solutions to meet your specific capacity and product goals.

- Comprehensive Support: Our commitment extends to complete project consultancy, seamless installation, operational training, and unparalleled 24/7 after-sales service across India, ensuring your mill runs efficiently for years to come.

A well-designed and efficiently operated rice processing mill is the backbone of a successful rice business. Partner with Ricetec Machinery to build a mill that not only meets today’s demands but is also equipped for the future of rice production.